Assess your readiness, minimize risks, and optimize your competitive advantage with these four critical steps for AM deployments.

You’ve probably heard of some pretty cool applications of 3D printing:

- 3D printed human heart? Check.

- Extraterrestrial AM construction to colonize Mars? Yep.

- A fully functional 3D printed Iron Man suit? You bet.

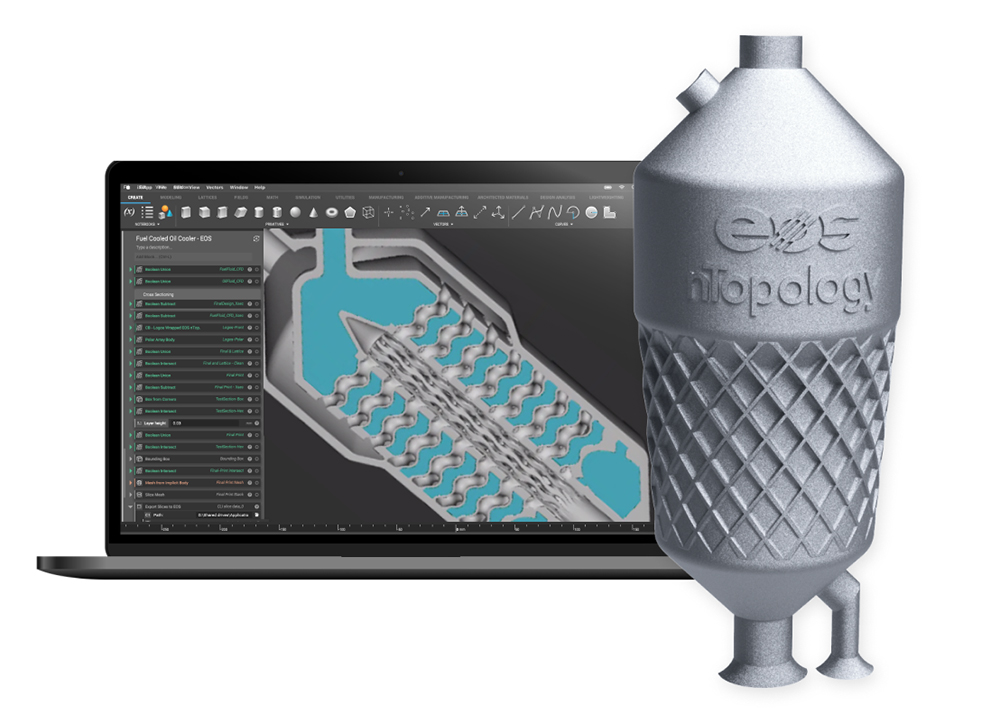

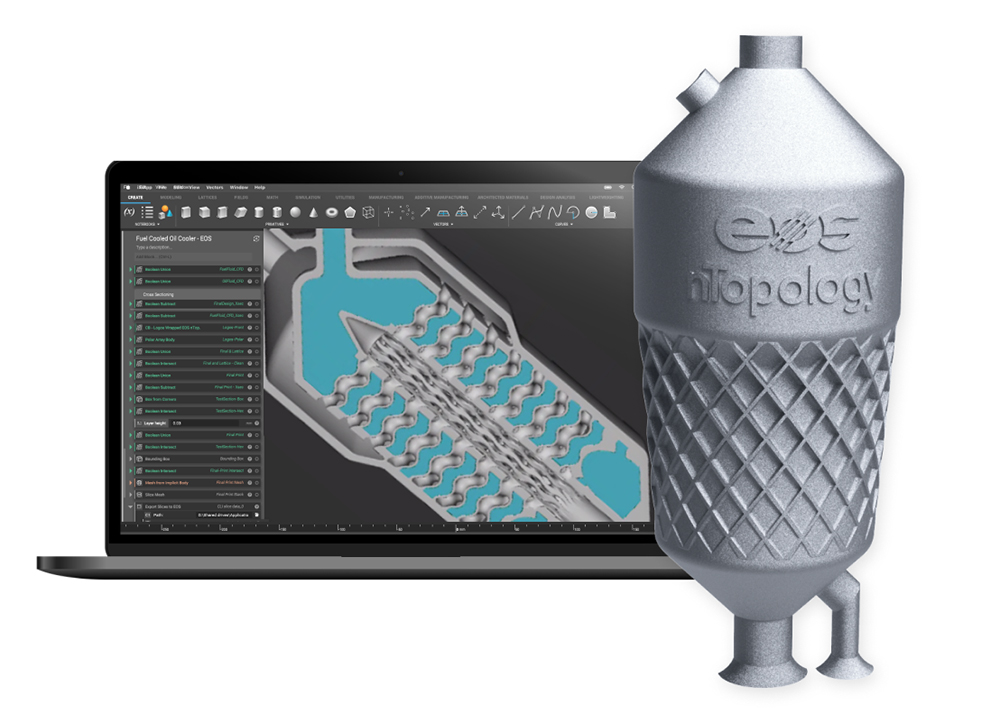

Maybe that last example won’t change the world, but the fact of the matter is industrial 3D printing, or additive manufacturing (AM), can be a game-changing technology for manufacturers.

It isn’t just about creating awesome stuff or fun, futuristic concepts, though. AM offers manufacturers real design freedom and flexibility through inherently sustainable manufacturing processes.

And it has come a long way since you last looked into it two or three years ago.

Flexibility is particularly important during times of change, like the current health crisis. While unprecedented, this event has shown us that our existing supply chains aren’t as robust or agile as we thought.

AM allows us to rethink how we manufacture and approach ever-changing disruptions. It enables highly flexible supply chains, reduces waste, enables print on demand capabilities, and creates new opportunities in the innovation field to produce applications that are higher performing than conventional parts.

So, why do so many companies struggle with implementing AM?

Humans have been essentially manufacturing things the same for more than 5,000 years. AM requires a new way of thinking.

The development of 3D printing applications for production is more complex than you may think. It’s often regarded like any other production technology, so people forget that it requires experience-based knowledge.

In this way, it’s more like a digital transformation of your operations.

If organizational leaders spent more time understanding the complexity of AM and setting themselves up to implement it into a work-stream or production workflow, then more organizations would have a smooth, uncomplicated transition.

How not to get stuck in pilot purgatory

When looking at companies that have struggled with AM, there are many similarities. The key is to realize that AM is a change strategy, and you’ll need a new approach for success.

Always start with a strategy

The first step in any AM journey doesn’t involve huge investments in technology at all. And it might be the most crucial step you take in achieving AM success.

Instead, it involves understanding what a successful AM strategy looks like.

Starting with the end in mind is key to creating a long-term strategy. To fully explore your AM opportunities, you’ll need to understand the challenges and solutions that will impact every level of your organization.

Rallying the team

The most successful companies using AM as a production technology form a transformation team that leads the transformation throughout your company and ecosystem of suppliers from beginning to end.

It’s essential to have representation within your team from every aspect of your value chain, including primary and secondary functions.

Also critical are executive sponsors to provide you with the support and resources, as well as the required pressure to push it forward.

In addition to the transformation team, you’ll eventually need a core implementation team once you have a better understanding of your use case. And it needs to be set up so it can function as an agile team.

Fill this implementation team with highly motivated people who have expertise with your current portfolio and can bring your AM initiative forward.

Defining a use case

You have your teams, now it’s time to identify a challenge AM can solve.

While you may be excited to develop a net new product or offering, starting with a current challenge in your ecosystem has its advantages.

First, starting in a problem space leaves you open to many solutions.

From a psychological perspective, solving challenges has a higher success rate as the buy-in will be greater. And, to be frank, everyone likes to chip in some time and effort if you can actually solve their problems.

Is there a bottleneck in your inbound logistics? Is slow-moving product piling up in your warehouse? Is cashflow limited, and your suppliers demand substantial minimum order quantities?

Think and challenge yourself to determine your internal challenges within your value chain and then work to understand how you can use AM to solve them.

However, even once you’ve identified a challenge, do the math to make sure AM is a cost-effective solution. This can be done through a Net Value Add analysis, which looks at the cost of AM production against the expected gains of using AM as a solution.

If the numbers work out in your favor – great! If not, move on to another challenge and begin the process again.

Knowledge is power

Sure, it’s a common saying, but internal knowledge is the key component to a successful AM implementation – and that knowledge needs to be shared broadly across your organization.

Utilize your transformation and implementation teams as thought leaders who can pass along what they’ve learned to others in your company. Ultimately, fostering internal knowledge will go far in sparking ongoing evolution of where and how to utilize and deploy AM for success.

Work on deploying knowledge sharing through training or information transfer sessions to ensure you’re not just teaching associates, but also empowering them to act.

Getting started

Your organization’s additive manufacturing journey will be like no other. That’s even the case if competitors are already using AM for similar applications and products.

By working with a partner with a proven ‘start to part’ experience, they’ll help ensure your AM journey is sculpted to your specific needs and yields a high return on investment. Not all partners have the capabilities or proven experience helping organizations get AM-ready or leverage it to its fullest extent.

But note that an average AM rollout takes around five years. If you want to be a first mover, it’s vital you get started today. The longer you wait, the less likely it is you will catch up to the competition.

Fabian Alefeld is the North American Manager for EOS’s Additive Minds consulting practice, which works with organizations across a variety of industries to maximize their efforts at every stage of the AM journey from start to part. For more information, visit www.eos.info.

The post Are You Set Up for Additive Manufacturing Success? appeared first on Industry Today.

,Assess your readiness, minimize risks, and optimize your competitive advantage with these four critical steps for AM deployments. You’ve probably heard of some pretty cool applications of 3D printing: 3D printed human heart? Check. Extraterrestrial AM construction to colonize Mars? Yep. A fully functional 3D printed Iron Man suit? You bet. Maybe that last example

The post Are You Set Up for Additive Manufacturing Success? appeared first on Industry Today.,Articles, Cited Content, Manufacturing, Technology